This case study demonstrates the value of ethnography and qualitative approaches in Latin American industry,...

This case study demonstrates the value of ethnography and qualitative approaches in Latin American industry,...

Agency and automation is explored through three case studies of the use of Cobots – collaborative robots – in three different auto production firms. The business challenges faced by these firms include labor shortages, quality control and reduction of waste. The Cobot solution resulted in...

A local division of a multinational manufacturer was experiencing declining enagagement and perceptions of leadership (measured in employee satisfaction surveys). In anticipation of coming waves of organizational change, they asked the research team to explore how “nostalgia” may be contributing...

Article 4 in the series Data, Design and Civics: Ethnographic Perspectives On April 1, Secretary of Defense Ashton Carter announced a $317 million federally funded initiative in textile innovation and manufacturing—a national consortium of public and private organizations to be led by MIT. It’s...

This paper sets out to explore how tangible tools can invite industrial managers to have a say in how ethnographic fieldwork can be conducted to explore the use of products in real-life contexts. We draw upon video materials and field notes from a series of customer visits in four European...

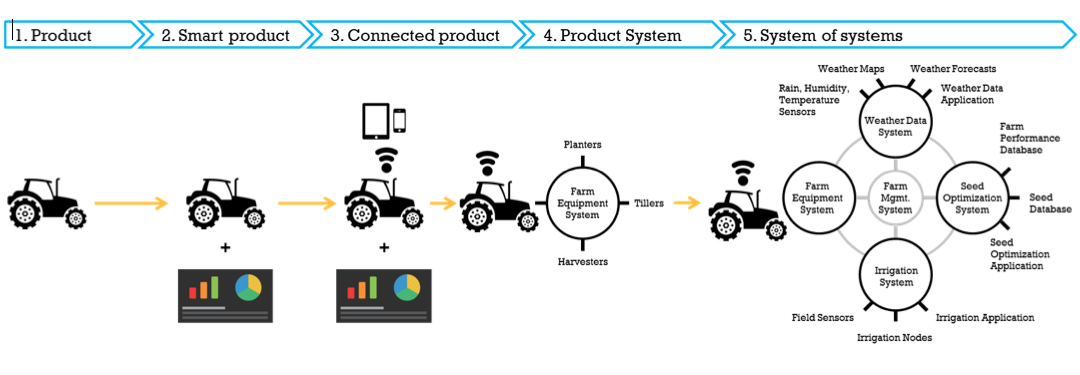

The Product Company Identity Crisis I have always worked at or with OEMs (original equipment manufacturing companies) in the industrial design and product development industry. The work has ranged from very large products such as sleeper cabins for long haul trucks and farming equipment down to...

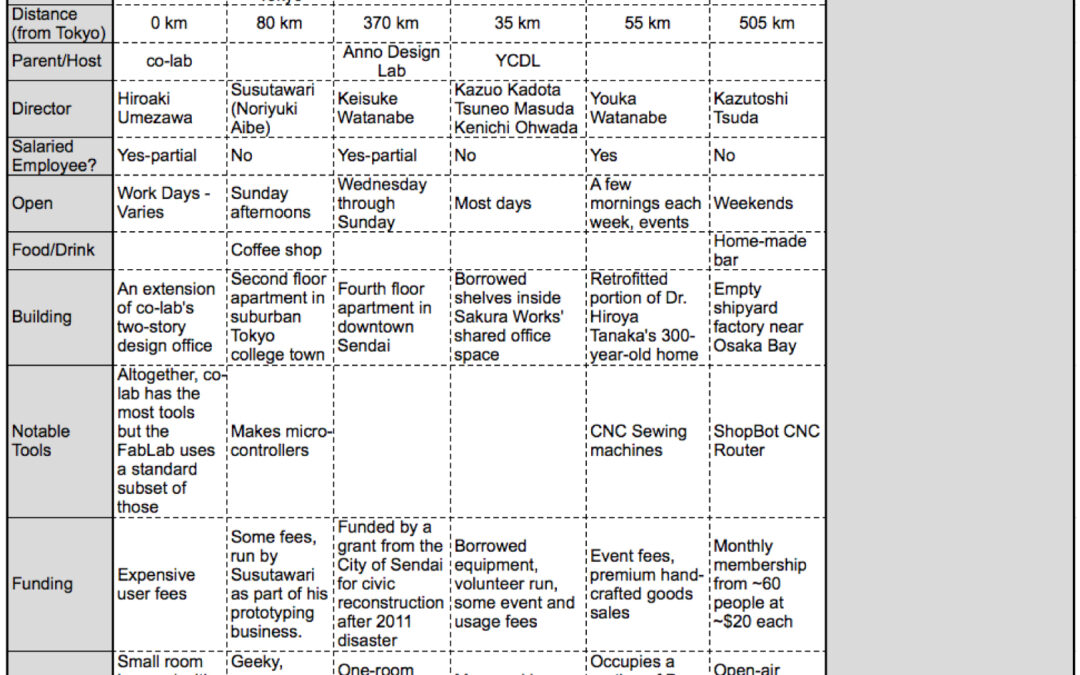

Manufacturing itself is changing as open-source sentiment grows with the “maker” movement, especially in FabLabs around the world. “Makers” are open-source hardware enthusiasts who want anyone to be able to make almost anything. This ethnographic research, conducted in 2013, centers on the...

This paper proposes a theory to explain how rural sociality has influenced workforce behavior and productivity at a Global Manufacturing Systems’ automotive assembly plant in mid-Michigan. The paper argues that for over 100 years, rural and farming families in the region have been appropriating GM...

A manufacturer of work clothes wanted to learn how workers use and experience its products to enhance marketing and sales. After a multi-sited field study, I learned that more critical than individuals or persona were the social practices that emerged within particular social units....

Research collaboration and methods development within user-centered design and the emerging discipline of user-driven innovation have traditionally taken place in research institutions and large forward-looking enterprises. Due to this fact, concepts, methodologies, approaches have primarily...